Welcome to Shandong Hongfan Power Technology Co.,Ltd

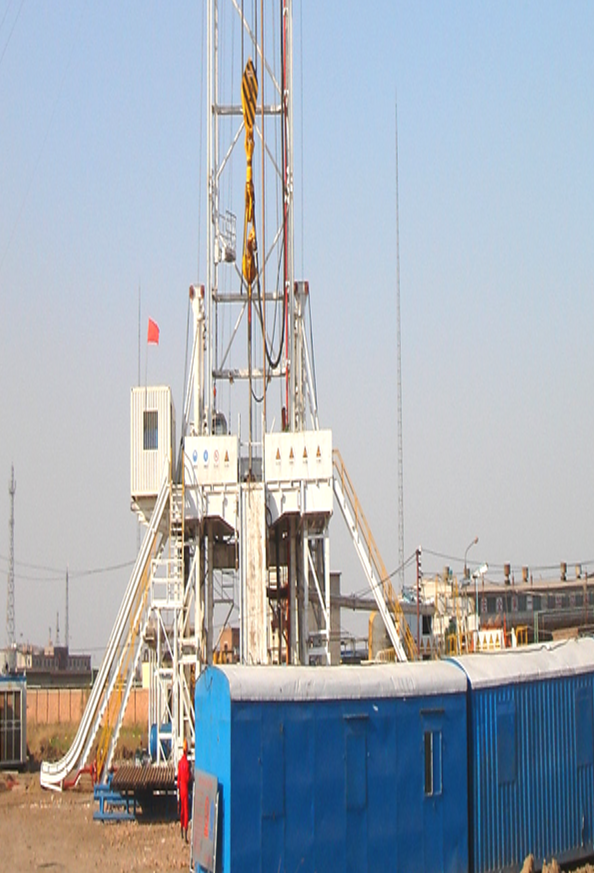

Basic Composition and Main Systems of Oil Drilling Equipment

Oil drilling rigs are complex engineering structures designed to perform heavy-duty tasks during drilling operations. A commonly used oil drilling rig mainly consists of four core parts: the power machine, transmission machine, working machine, and auxiliary equipment. It must possess three basic capabilities: lifting the drill, rotating and drilling, and circulating and washing the well.

In this article, we’ll provide a comprehensive introduction to the main drilling equipment, their systems, components, and functions to better understand how a drilling rig operates.

Main Equipment of a Drilling Rig

A standard oil drilling rig includes the following primary equipment:

Derrick

Overhead crane

Winch

Traveling block

Big hook

Turntable

Faucet (power swivel)

Drilling pump

Power machine (diesel engine or electric motor)

Transmission (linkage) machine

Solid control equipment

Well control equipment

I. Main Systems and Equipment of the Drilling Rig

A complete drilling rig is built from several integrated systems, including:

1. Lifting System

Responsible for moving the drill string and casing up and down the wellbore.

2. Rotation System

Provides the rotational force required to drill into the geological formations.

3. Drilling Fluid Circulation System

Circulates drilling fluid (mud) to remove rock cuttings and cool the drill bit.

4. Transmission System

Transfers and distributes power from the energy source to the working components.

5. Control System

Ensures that all equipment can be controlled reliably, safely, and centrally.

6. Power Drive Equipment

Provides the necessary mechanical or electrical energy to power the rig operations.

7. Drilling Rig Base

Serves as the foundation for mounting major equipment, ensuring stability.

8. Auxiliary Equipment

Supports various operational needs like power, water, oil, gas supply, and storage.

II. Rotation System

Composition:

The rotation system includes the turntable, faucet (power swivel), and downhole drilling tools.

Function:

Its primary role is to drive the drill bit and other drilling tools to rotate and crush underground rock layers. It also connects to the lifting and drilling fluid circulation systems.

III. Drilling Fluid Circulation System

Composition:

Key components are the drilling pump, surface manifold, riser, faucet, mud preparation and purification equipment, drilling tools, and drill bit nozzles.

Function:

This system flushes the well bottom, carries drill cuttings to the surface, cools the drill bit, and transmits hydraulic energy downhole.

IV. Transmission System

Composition:

The transmission system includes various interlocking machines and components connecting the power machine to the working machine.

Function:

Its main role is to transmit and distribute power efficiently to various working units.

V. Control System

Composition:

The control system integrates mechanical controls (handles, pedals, joysticks), electrical controls (relays, resistors, microcontrollers), and pneumatic/hydraulic controls (working cylinders, gas-liquid components).

Function:

It enables precise, fast, and safe control of all working machines, ensuring smooth drilling operations and enhanced safety through central management.

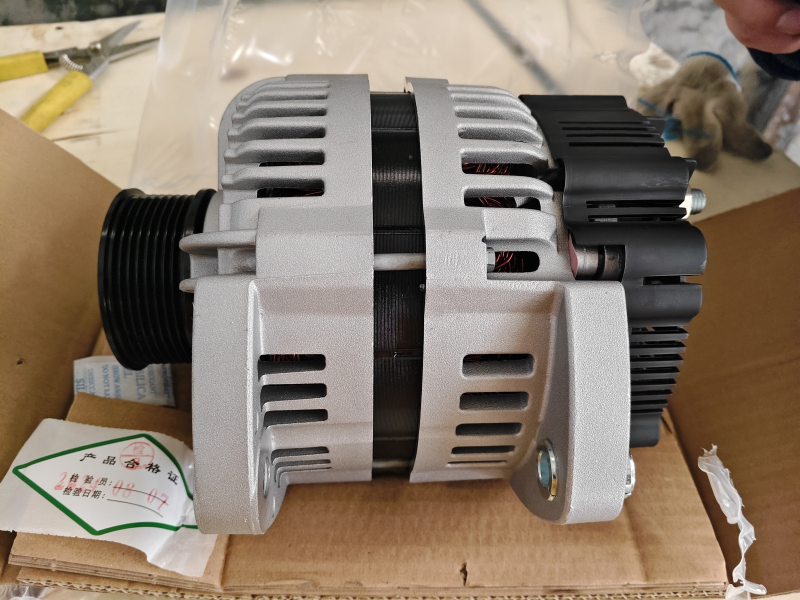

VI. Power Drive Equipment

Composition:

Includes diesel engines, electric motors, gas turbines, and steam turbines. Power sources can be single or combined systems.

Function:

This equipment provides the necessary power to drive all mechanical operations on the drilling rig.

VII. Drilling Rig Base

Composition:

Made up of the platform base, machine room base, drilling pump base, and auxiliary equipment base.

Function:

The base secures and stabilizes the drilling rig, facilitates relocation, and supports wellhead equipment installation. It also provides safe and convenient access for operators.

VIII. Auxiliary Equipment of the Drilling Rig

Composition:

Includes systems for power supply, gas supply, water supply, oil supply, equipment storage, blowout prevention, mud preparation and storage, and various monitoring instruments.

Function:

These systems meet the comprehensive technical and operational needs of the drilling process, ensuring safe, efficient, and uninterrupted operations.