Welcome to Shandong Hongfan Power Technology Co.,Ltd

Complete Overview and Components of the F-1000 Mud Pump Package

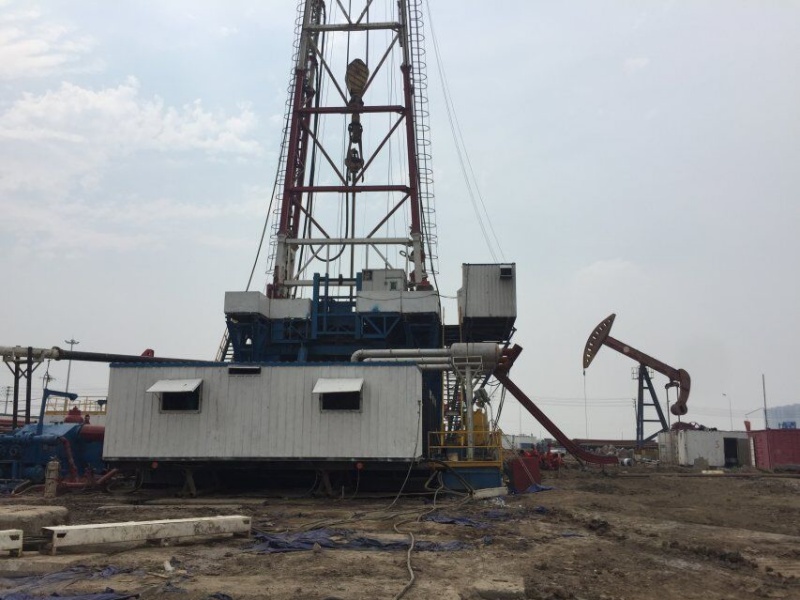

In the oil drilling industry, the mud pump package is a critical piece of equipment responsible for pressurizing drilling fluid and providing the necessary energy for circulation. This article takes the F-1000 mud pump package as an example to detail its components, functions, and performance features, helping industry professionals better understand the full setup and operation of a mud pump system.

Core Function of the Mud Pump

The primary function of the mud pump is to pressurize drilling fluid, allowing it to circulate through the wellbore, carry cuttings to the surface, cool the drill bit, and stabilize the wellbore pressure. The F-1000 model includes an air bag, safety valve, and extended base to ensure stable and safe operation.

Types of Prime Movers and Their Functions

To ensure efficient operation of the mud pump, high-performance prime movers are essential. Common types include:

Diesel Engine: Converts thermal energy from diesel combustion into mechanical energy, ideal for field operations and areas with limited power supply.

Electric Motor: Converts electrical energy into mechanical energy, featuring high efficiency, cleanliness, and ease of maintenance.

Gas Turbine: Converts natural gas combustion into mechanical energy, suitable for high-power requirements with fast response times.

Transmission System (Compound Machine)

The transmission system serves as the link between the prime mover and the working machine, distributing the power efficiently. It consists of synchronization devices, reversing mechanisms, speed reducers, torque increasers, variable speed and torque devices, and directional conversion systems, ensuring stable operation under various working conditions.

Standard Configuration List of F-1000 Mud Pump Package

The main components and specifications of the F-1000 mud pump package are listed below:

| No. | Name | Specification/Model | Unit | Quantity |

|---|---|---|---|---|

| 1 | Mud Pump (with air bag, safety valve, extended base) | F-1000 | Set | 1 |

| 2 | Hand Crane, maximum 0.5 tons | Hand crane, 0.5 tons | Set | 1 |

| 3 | Manifold System (4" valve, 2" discharge valve, 3m hose, etc.) | 35 MPa | Set | 1 |

| 4 | Perfusion System (electric-driven perfusion pump, butterfly valve, pipelines, filters) | SB5×6-11.5 (Flow 160 m³/h, Head 28 m, 30kW) | Set | 1 |

| 5 | Mud Pump Console | Mud pump console | Set | 1 |

| 6 | Coupler and Mud Pump Transition Flange | - | Set | 1 |

| 7 | Mud Pump Input Flange | - | Set | 1 |

| 8 | Protective Cover | Protective cover (1 piece) | Set | 1 |

| 9 | Universal Coupling | Universal coupling | Set | 1 |

| 10 | Diesel Engine Coupler Assembly | CO810F-3/22 (G12V190ZL-3 engine + YOTFJ750 coupler) | Set | 1 |

| 11 | Muffler | - | Set | 1 |

| 12 | Muffler Support Bracket | - | Set | 1 |

| 13 | Battery (For diesel engine) | - | Set | 1 |

| 14 | Battery Charger | - | Set | 1 |

| 15 | Fuel Tank (for 8-hour operation) | - | Set | 1 |

| 16 | Common Base for Diesel Engine and Coupler | - | Set | 1 |

| 17 | Remote Control System | - | Set | 1 |

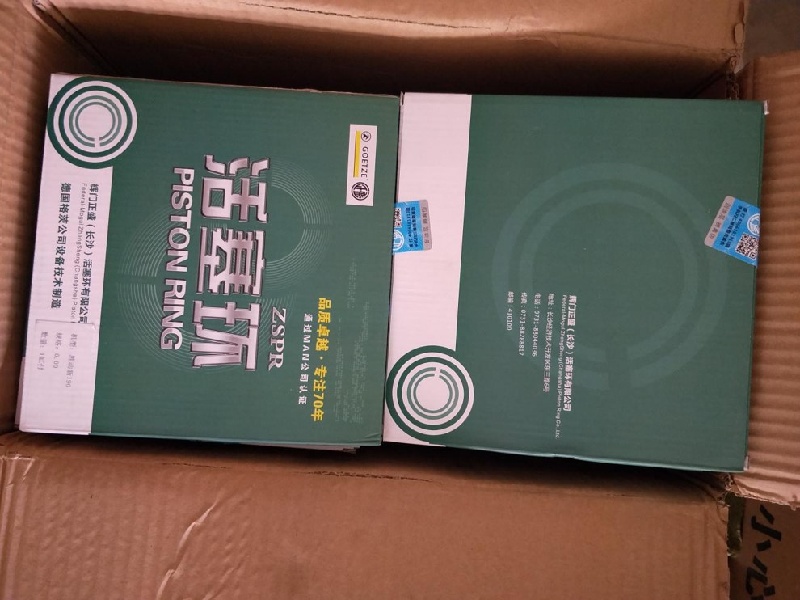

| 18 | Mud Pump Spare Parts | - | Set | 1 |

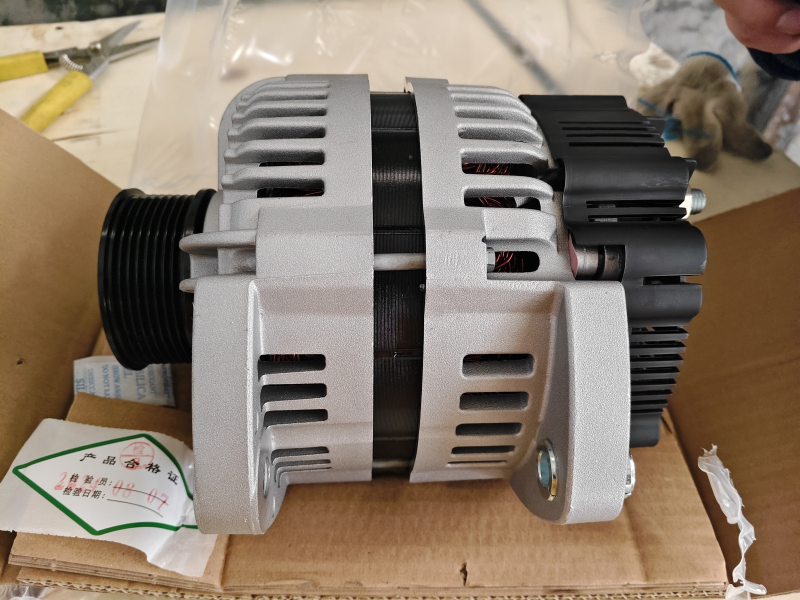

| 19 | Diesel Engine Spare Parts | - | Set | 1 |

| 20 | Mud Pump Service Tools | - | Set | 1 |

| 21 | Diesel Engine Service Tools | - | Set | 1 |

| 22 | Equipment Certificates and Manuals | - | Set | 1 |

Conclusion

As an indispensable piece of equipment in oil drilling operations, the F-1000 mud pump and Jichai G12V190PZL diesel engine offers perfect configuration and reliable performance. Whether driven by diesel engines, electric motors, or gas turbines, it can be flexibly matched according to different operational requirements, ensuring smooth drilling processes in a variety of conditions.